Dmg Mori Davis Ca

Posted : admin On 10/19/2019View Vinh Hoang’s profile on LinkedIn, the world's largest professional community. Leading DMG MORI SYSTEMS Production Team Leading DMG MORI SYSTEMS Production Team. Jan 01, 2014 DMG MORI has announced record attendance at its inaugural Manufacturing Days event, the Open House of the Davis factory. The four-day event, held November 12-15, brought more than 1,300 visitors through the company's U.S. Manufacturing facility and the adjacent Digital Technology Laboratory (DTL) in Davis, CA. Company logo Mori Seiki is a Japanese manufacturing company of precision machines, most of which would seem pretty mysterious to those of us without engineering backgrounds. In addition to the Digital Technology Laboratory that already exists in Davis, the company's first North American factory was completed in Davis in 2012. It was estimated that the factory would employ between 100 and 150. Steve's Pizza Davis added a new photo — at DMG/MORI SEIKI USA Inc. September 17 at 12:17 PM Davis, CA KetMoRee Thai Restaurant & Bar added 7 new photos to the album: Catering — at DMG/MORI SEIKI USA Inc. Performance at a level above your competition. The CMX 1100 V, made in Davis, CA, is equipped with over 200 options for workpiece handling, monitoring, measurement and machining.

Attendees saw the U.S. premier of two five-axis machining centers. They also saw vertical machining centers and the company’s advanced machine tool factory.

New to the U.S. market is the DMU 75 MonoBlock, a five-axis machining center that balances a relatively compact footprint (less than 86 square feet) with a relatively large work envelope for parts measuring as large as 33 inches in diameter and weighing as much as 1,322 pounds. Free dmg to iso converter. The demo at Davis emphasized the accessibility of the configuration (it enables loading with a crane) and the flexibility of the swiveling rotary table. The machine was shown with a FANUC control unit using the Celos interface and Mapps digital operating system.

The cubic fixture in the demo on the DMU 75 had five-sided workholding with multiple parts on some sides.

Dan mintz jokes. “We’re partnering with a team of trailblazing leaders in this rapidly growing industry to push new boundaries and bring mind-blowing VR experiences to the world.”The Arcturus team is led by key industry pioneers with decades of combined experience in the interactive and storytelling space.

Also making its debut was the DMU 90 P DuoBlock, a five-axis machine configured with a rotary head over a rotary table. The “P” designation indicates that it is powered for heavy-duty machining of large workpieces as heavy as 3,970 pounds. Its stated positioning accuracy is 4 microns. X-axis travel measures 35.4 inches. This machine is described as “an economical entry into machining of die/mold work and aerospace structural components.”

The demo on the DMU 90 P, however, showed the maneuverability of the machine working around a rock drilling head that featured complex contours, holes at odd angles and deep recesses.

The DMU 50 shown here is built in Davis. The demonstration of this universal machining center featured a prototype steering knuckle for a sports car. The machine has full five-axis capability, but the point of this demo was to show how the 3+2 mode enables a complex part to be completed in only two operations.

By positioning the workpiece for access by the highly flexible orientation of the cutting tool on the DMU 50, this steering knuckle needs only one refixturing to be machined completely. As many as five setups might be needed without the five-axis positioning of this machine.

Three versions of the CMX 1100 V machine were on display to show how this platform can be “packaged” for the various needs of job shops looking for a boost in their vertical machining capability. The CMX 1100 V is the largest of the machines in this series and the best-selling size (the CMX 600 V and the CMX 800 V have smaller tables). The version shown here represents the “value” package with the basic features included to give an entry-level machine with 55 inches of X-axis travel and a 12,000-rpm spindle. The “performance” package displayed nearby looked nearly identical, but features a 15,000-rpm spindle and is prepped for on-board probing, coolant and filtration options plus automation. The CNC has more advanced features as well.

This CMX 1100 V definitely has a distinctive appearance because it is equipped with a VersaBuilt roboticized part loader/unloader.

The self-contained VersaBuilt unit is designed to easily swing away from the machine. This enables the machine to be operated manually without obstruction and the unit to be served easily.

The key to this unit’s success is the robot’s ability to load and unload vise jaws along with loading and unloading workpieces, all automatically. The robot can switch from loading and unloading one type of workpiece to another by quickly exchanging the jaws needed for the new part. Developers say this flexible, automated system can out-produce an HMC with a pallet changer when part mix is high and batch sizes are on the low to medium size.

DMG MORI’s Messenger software is a complete>PreviousNext

Read Next

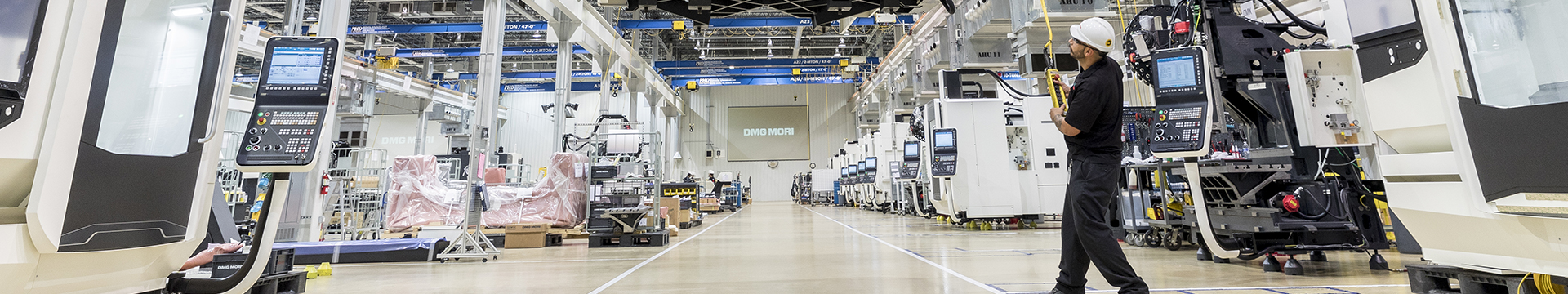

Davis, California, is a satellite community of Sacramento, the state’s capital, and the location of the University of California’s Davis campus. Davis is also home to DMG MORI’s Digital Technology Laboratory and its North American manufacturing plant. During the company’s Technology Days event Nov. 13-16, customers and journalists had the opportunity to see the U.S. premier of two five-axis machining centers, a variety of vertical machining centers, and the company’s advanced machine tool factory.

One theme that connected all of these sights was an emphasis on “digital connectedness”—the ability to organize and manage production with current, detailed data, which is the essence of the Industry 4.0 concept.

RELATED CONTENT

Mori Seiki Mill

Increase Machining Efficiency through Machine Monitoring

A manufacturer that is distinctive for its attention to in-cycle machining productivity describes its efforts to obtain efficiency improvements outside of the machining cycle. The shop’s primary tool is a simple, daily, graphical recap that illustrates when each machine tool was and was not making parts.

An Overview Of 3 + 2 Machining

You don't have to use all five axes of a five-axis machine at the same time to get great benefits. Here's what 3 + 2 can do for you.

Composites Machining for the F-35

Lockheed Martin’s precision machining of composite skin sections for the F-35 provides part of the reason why this plane saves money for U.S. taxpayers. That machining makes the plane compelling in ways that have led other countries to take up some of the cost. Here is a look at a high-value, highly engineered machining process for the Joint Strike Fighter aircraft.

As you were browsing www.whitepages.com something about your browser made us think you were a bot. There are a few reasons this might happen:

Dmg Mori Davis Factory

- You're a power user moving through this website with super-human speed.

- You've disabled JavaScript in your web browser.

- A third-party browser plugin, such as Ghostery or NoScript, is preventing JavaScript from running. Additional information is available in this support article.

Dmg Mori Manufacturing Davis Ca

To request an unblock, please fill out the form below and we will review it as soon as possible.